Process Control Room Solutions

Process control centres continuously monitor and control constant flow of manufacturing, industrial control processes, infrastructure/equipment status, and the dynamic change on demand, to guarantee production and distribution in the best way possible . The challenges include providing an integrated real-time overview of process flow and equipment status for better situational awareness, and decision making, along with a flexible and ergonomic system deployment for efficient yet managed access to devices. Information integration and visualization are especially important in these scenarios—from detailed network distribution information to topological overviews of the service area—in addition to redundancy/backup support to ensure continuous operations.

Uninterrupted Process Control

With the increasing application of process automation in the industrial sector, there is a high expectation from the visualization tools in video wall control rooms. Monitoring and sharing the ever-expanding amount of video and data streams are essential for control rooms. High-quality video performance, along with the best resolution, makes possible a rapid analysis of evolving situations and real-time decision-making. These control rooms need to be equipped with the most reliable, effective and scalable systems, and displays for uninterrupted operation.

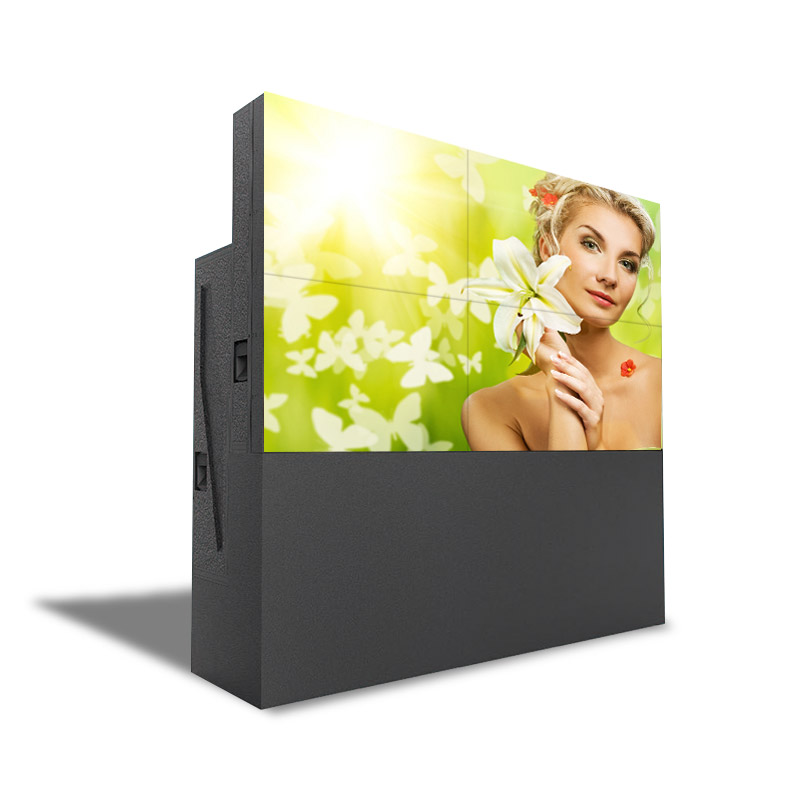

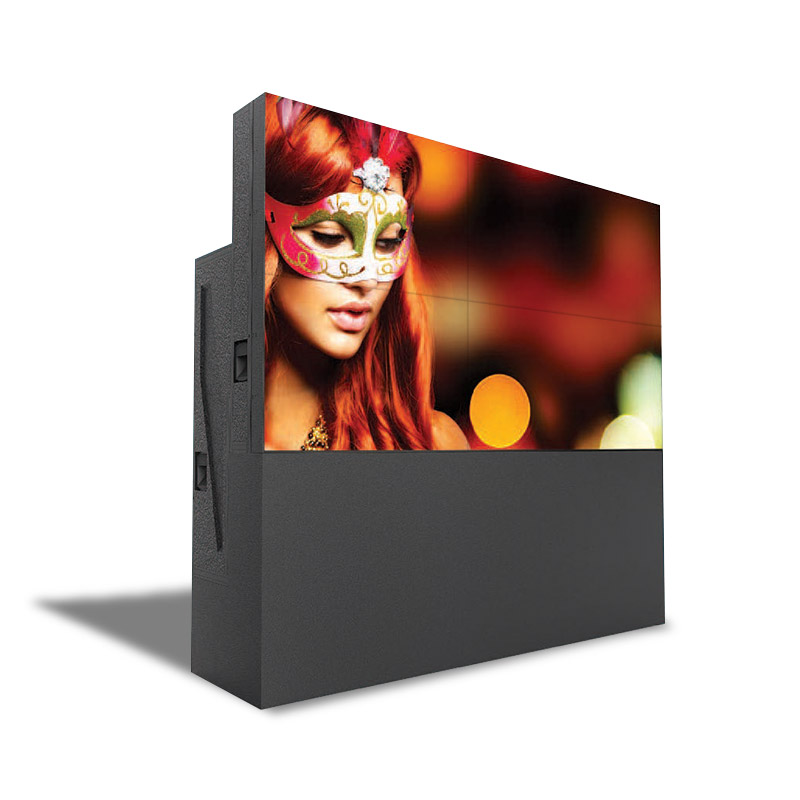

Delta Video Wall for Mission-Critical Applications

The cubes used in all Delta rear projection video walls are powered by DLP technology, generating extraordinary image quality with incredible colour depth and contrast. Ideal for 24×7 operations, Delta’s High Resolution Large Screen Displays enable information sharing and analysing mission-critical applications in real time.

Process Control Rooms

- Oil & Gas

- Sugar plant

- Cement and many more Process Applications